I used to have a record player. A long time ago. I used to have an old stereo from my grandparents, which looked a bit like this. It was a great system, which already has aux-in, microphone-in, and I connected an old Uher tape recorder to have a great Hifi System. But, as time went on, CD players came, and I got a new, more compact stereo with a three disk CD player and was the greatest thing for me as a 12 year old. Of course it was not as good, as the old one, but I did not notice that at the time.

For a long time I did not think a lot about records, until a few years ago, when most of the music started to not only be in digital form, but also to come in the form of streaming. I started to consume music, rather than listen to it. And I think a lot of people do. It did not bother me, until I noticed, that I did oftentimes not know, which band I just had heard. This was when I decided, that I really wanted to celebrate music, really listen to it, rather than hear it as some appreciated background sound. Most musicians put a lot of effort in their records, a lot of sweat, and an immense amount of rehearsing and training. A lot of records are really a concept and not just a random playlist. I really wanted to appreciate that more.

The solution for me was to buy a record player. With that, I would have to put some effort into listening to music. I would have to choose a record, pull it out of its sleeve, smell the age of the carton, carefully put it on, clean it and then drop the needle. In difference to a CD, a record would need much more care, but also create a ritual, that I wanted to train myself to appreciate music more again.

The old Dual record players have been a recommendation to get a good, reliable record player for little money. I decided to look for a belt drive machine, rather then direct drive, which is said to only be really better in the still expensive high end devices of the time, or the earlier idler wheel drive systems, which are said to be prone to introduce a rumbling sound.

I found a good offer for a Dual 510 which was introduced in 1976. It came with an unused Ortofon MX 3 MC which I installed and started listening. It was great, but after a few records, the record slowed down. So I used the pitch control to adjust it, but after a few minutes it slowed down, until it was barely moving.

The first thing I did, was to change the belt and the suppressor capacitor. To change the belt, there is a screw, which has to be losened, which holds a lever, which keeps the table in place. It is nicely illustrated in the manual. The exchange is pretty straightforward, but you should clean everything the belt touches with isopropanol for maximum traction. To change the capacitors, you have to take the player out of its cabinet, which is simply done by losening the screws and shift them away from the center, then it can be taken out and carefully layed on a smooth surface. The insides of the player can be seen here. Measurement of the capacitor showed, that it was not far off, but the original is said to be prone to vanish smoke and an awful smell after a few decades, so I replaced it.

Sadly, this did not do the trick. The next thing I looked at, was the pitch control.

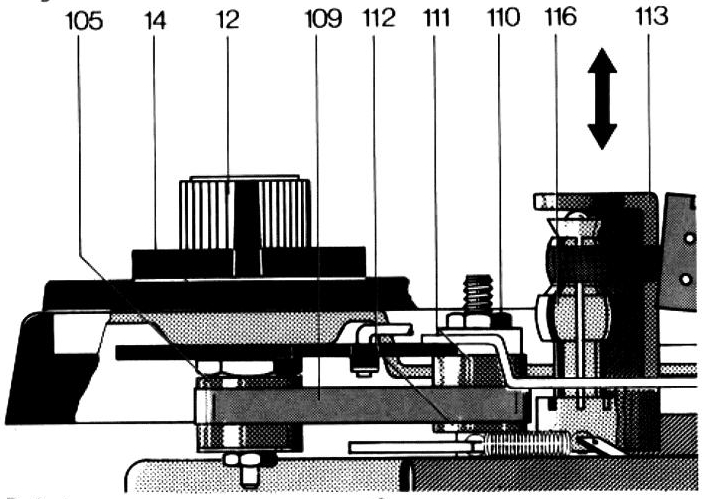

The picture shows the sketch from the manual. The pitch control is parts 113 and 116. Part 113 is mounted on top of the motor and drives the belt. It has two areas, where the belt can run. A smaller one for the slower 45 and a larger one for faster 33 mode. Changing the mode just moves the belt on this part. The belt drive is built in such a way, that its top consists of several pieces which are held together by rubber bands. Turning the pitch control knob results in the lever part 116 moving up or down. This moves a cone in or out of the belt drive, changing the circumference of the area, the belt touches. Quiet great, right?

I noticed, that the lower part of the pitch control touched the upper sintered bearing of the motor, meaning, it was way to low. It is held in place of the axis by a grub screw. After adjusting it, I thought, now I have it. But I was wrong. Same as before. Half a record later, I had to reopen the player.

So.. I had to take a closer look at the sintered bearings of the motor, which are incorporated in its mounting:

On the upper picture, the abrasion of the aforementioned "touching" can be seen quite clearly. The real Problem was found, when I had a closer look at the inside of the lower bearing:

The sintered bearing is held in place by a piece of steel sheet. The steel sheet is held in place by very tiny parts of the motor mount. The last remaining ones can be seen in the upper picture on the left and on the top. Two of those had already broken of, leading to a situation, where the steel sheet could pop out. Now, this was particularly bad, because a lose bearing means, that the axis is not held in place and the axis has the anchor of the motor mounted on top of it. Now, if the magnetic fields in the motor meet a lose anchor, the anchor does not only rotate, but it is pushed to the side, pushing the bearing to the side and thus blocking the rotational movement. Because a new part is hard to come by for a record player, which is not build for 40 years, I had to fix it. And here is how I did it:

First I glued the steel sheet into place with locktite:After that, I had to put everything back together and enjoy the device. It has been working flawlessly ever since.

This repair was really interesting. I have not put much thought into how a record player really works. This Dual is really a great example, how simple these devices are and how complicated at the same time. All the moving parts have to work just perfectly, but all the concepts are so simple that you really can keep them running for a very long time.